It has been too long since my last Build post but I have not been snoozing in the cockpit. Seems the work moved from large components, like wings and surfaces, which are easier to show off…to a million-and-one small things, which are not photogenic. Covering remains for the tail control surfaces but the remainder of the plane is covered…with Sig Koverall and Nitrate Dope. A respirator is a must to preserve brain cells. I swear the Sig Stix It adhesive is worse than the Dope. 90% of the wiring has been plumbed and the lighting installed. Flying wires are built and ready for tensioning. I built a central control panel containing RXs, GPS, variometer, lighting controller, etc which will be removable from the aircraft.

Much of what remains is cosmetic. Fin-to-stab fillets, fuse-to-wheel-fairing fillets, fairing-to-wheel-paint fillets, cabane wire covering, hatch covers,… I have yet to determine battery placement for establishing center of gravity but that comes after bolting on the motor. Today I am updating my punch list to ensure I don’t miss anything. (And to see how much truly remains, scary thought!)

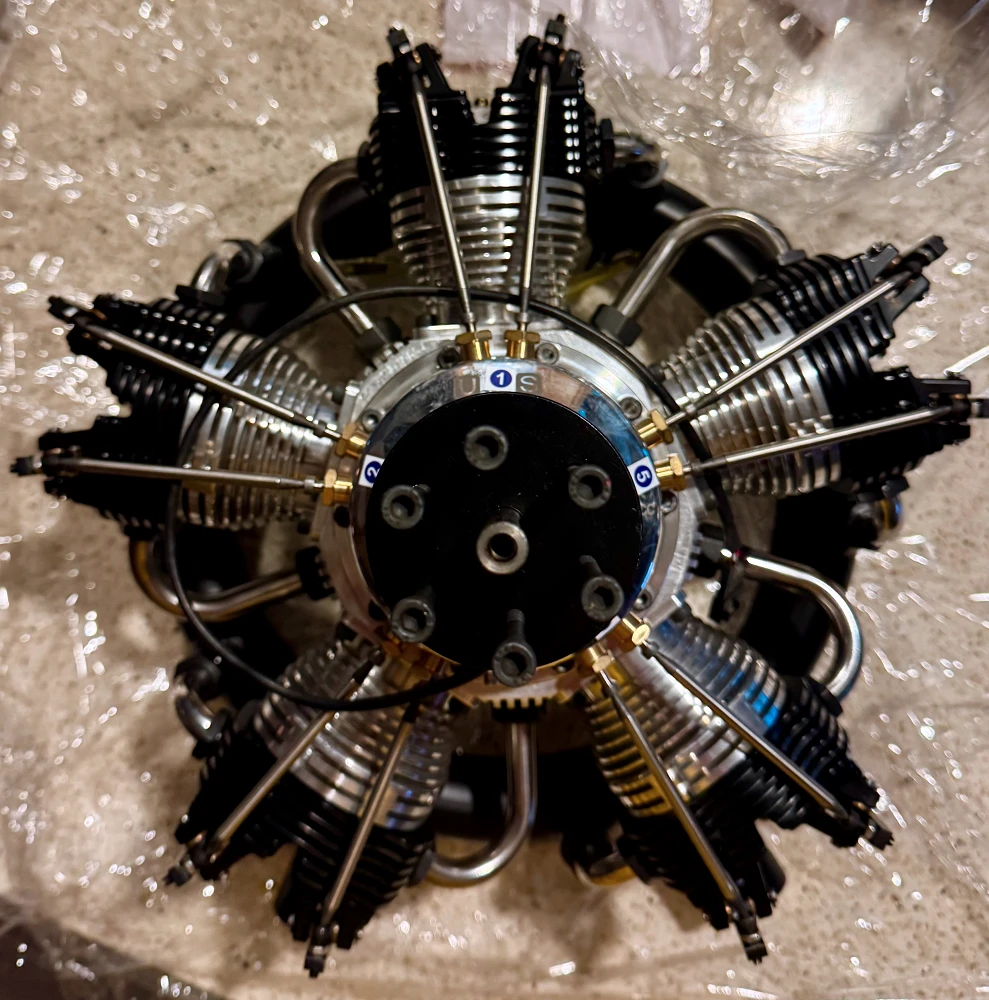

The motor selected for this big bird is the UMS 5 cylinder 210 cc radial. Definitely overkill but it’s gonna be fun. It will swing a 32×10 Xoar wooden propellor around 5,000 RPMs and expected to idle at 950 RPMs. The motor needs a gallon of gas to break-in so I am working on the test stand setup (borrowed from RG) right now. I expect to have it at the Field in the coming days to turn-n-burn…some gas. My biggest paranoia is bolting this 10 pound behemoth onto the firewall. Will the firewall stay in the plane! The all-up weight is likely to be 45 pounds.

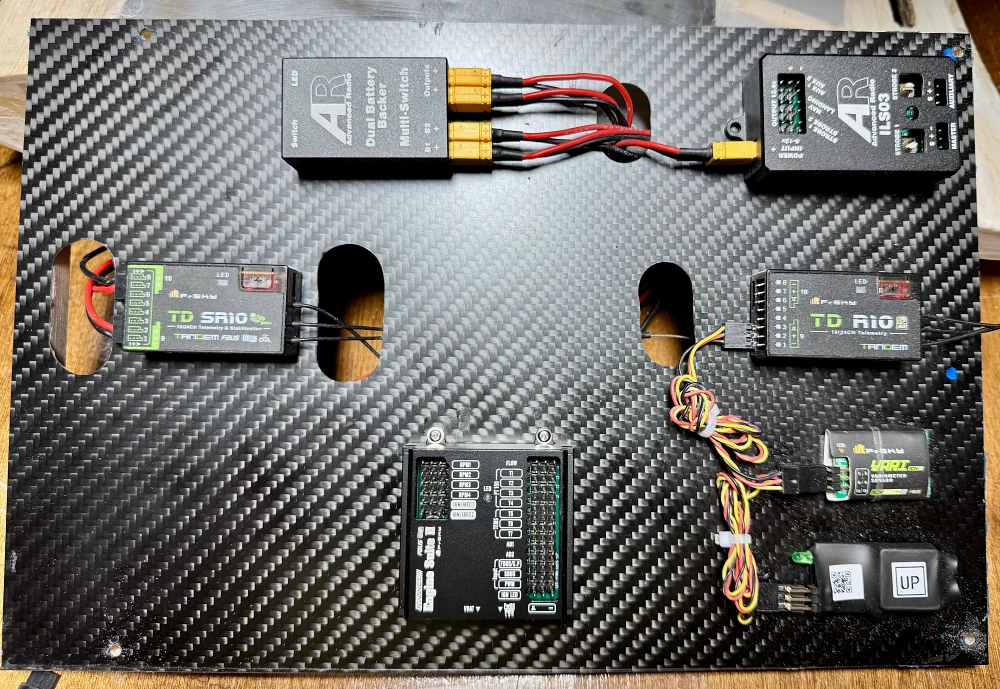

Given this is a LARGE platform I am incorporating geeky gadgety things I have never used before. I fly Frsky gear so adding their telemetry items such as GPS, variometer, airspeed pitot and the Advanced Engine Suite. Also adding a stall speed indicator, recently featured in July/August Model Airplane News. Why not? I want to add a head-tracking FPV camera setup but likely will install it on a more “disposable” aircraft first.

The FRSKY Advanced Engine Suite II (AES II) is a multi-functional management box suitable for application in airplanes equipped with gasoline engines. Users can use the same battery to power all connected devices, eliminating the trouble of providing an independent power supply for the ignition control unit. AES adopts a solution to avoid interference between the connected ignition and receiver devices. It is equipped with a wealth of sensor interfaces, including 4 RPM sensors and 7 temperature sensor ports. At the same time, through the connected receiver, users can monitor the telemetry data in real-time on the transmitter to know the aircraft’s operating status.

My intent is to fly the Waco before painting and detailing. Shake it out, get it trimmed, etc and then spend the winter months making it pretty. Many of you have asked so….yes, it will fly in the near future. I will post WHEN on our FB group as I know you are wanting to be there. But you have to promise to BE QUIET so I can focus. LOL!

Click to see other articles on Spirits Build Projects

Latest Comments:

Ralph, That is a brilliant looking plane and I’m sure a cool experience for yourself. The added historical content and…

“For he’s a jolly good fellow”…Thanks for a wonderful evening Steve!

Awesome article…what engine was in it?

Awesome…that was a lot of fun sharing the water and sky with some great guys! Special thanks goes to Steve…

Supertigre GS-51